Elite Automotive Services

Voted “Best In Orange County” By The Orange County Register.

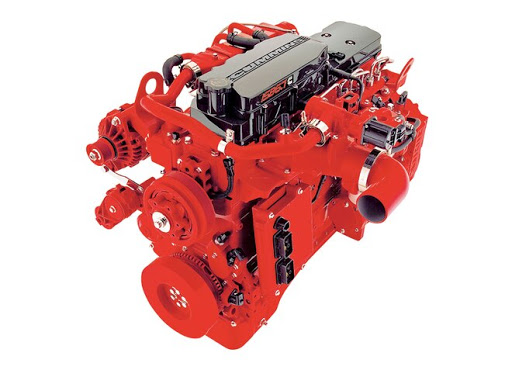

Diesel Repair and Diesel Services

26801 Vista Terrace Lake Forest, CA

eliteautomotiveservice.com

ELITE AUTOMOTIVE SERVICES

We Are Your Certified Diesel Technician Professionals in Lake Forest, Ca.

Since 2009, we have been working on Light, Medium, Heavy-Duty Diesel Trucks in Lake Forest and the surrounding areas. We are the leaders and trend-setting diesel repair shop in Orange County, Ca. Our Diesel owners continue to return to us for the quality parts, service, and repairs that we offer. We are a full-service diesel shop that performs anything from routine diesel service to complete diesel engine rebuilds and everything in-between. Our Factory Trained Award-Winning Diesel Technicians only use high-quality parts to ensure the job is fixed right the first time, on time, all of the time. We offer the best warranty in the industry, 3-years/36,000 miles.

ELITE AUTOMOTIVE SERVICES

Our Diesel Technicians have 30 plus years of diesel repair experience We focus on Light, Medium, and Heavy-Duty Diesel Trucks, repair, service, and performance from bumper to bumper in the Lake Forest, Orange County area. We have Ford, Dodge, Chevy, CAT, Cummins and International Factory Trained Technicians that use Factory Diagnostic Scanners for Diagnosing, Programming, and Reflashing. At our 30,000 square-foot state-of-the-art facility, We have the latest technology and equipment to address all of your fleet vehicle concerns. We are indeed a one-stop-shop for your business with any size fleet. We are proud to be voted “The Best Shop In Orange County.” By our guests and the Orange County Register.

ELITE AUTOMOTIVE SERVICES

Voted “Best In Orange County” By The Orange County Register.

Diesel Services With the use of factory diagnostic equipment and over thirty years of experience, we diagnose any diesel concern you may be having with your vehicles. Utilizing diagnostic routines and best practices is the most efficient way to pinpoint any cause of any problem and repair them. Our Factory-Trained Diesel Technicians focus on:

- Fuel Systems

- Turbochargers

- Engine repairs

- DrivabilityPerformance

- Electrical Concerns

- ABS Brakes Systems

- Suspension Systems

- Air-Ride Systems

- Air Conditioning

- and all other matters that you may be experiencing.

Inspection We thoroughly inspect your vehicle to detect any current or future problems you may have.

Diesel Frequently Asked Questions

How to repair a diesel fuel pump?

An Injection Pump is a device that pumps fuel into the cylinders of a diesel engine. Traditionally, the pump is driven indirectly from the crankshaft by gears, chains, or a toothed belt. It rotates at half crankshaft speed in a conventional four-stroke engine. Its timing is that the fuel is injected only slightly before the top dead center of that cylinder’s compression stroke. Earlier diesel pumps used an in-line layout with a series of cam-operated injection cylinders in a line, rather like a miniature in-line engine. The pistons have a constant stroke volume, and injection volume is controlled by rotating the cylinders against a cut-off port that aligns with a helical slot in the cylinder. When all the cylinders are rotated at once, they simultaneously vary their injection volume to produce more or less power from the engine. In-line pumps still favor large multi-cylinder engines such as those on trucks, construction plants, stationary engines, and agricultural vehicles. For use on cars and light trucks, the rotary pump was developed. It uses a single injection cylinder driven from an axial cam plate, injecting into the individual fuel lines via a rotary distribution valve. Later incarnations such as the Bosch VE pump vary the injection timing with crank speed to allow greater power at high crank speeds and smoother, more economical running at slower revs. Some VE variants have a pressure-based system that allows the injection volume to increase over normal to allow a turbocharger-equipped engine to develop more power under boost conditions. All injection pumps incorporate a governor to cut fuel supply if the crank speed endangers the engine – the heavy moving parts of diesel engines do not tolerate overspeeding well, and catastrophic damage can occur if they are over-revved. Mechanical pumps are gradually being phased out to comply with international emissions directives and increase performance and economy. Alternatives include standard rail diesel systems and electronic unit direct injection systems. These allow for higher pressures to be developed and adequate control of injection volumes compared to mechanical systems.

How to repair a diesel generator?

The need for reliable backup electric power is too important to leave to chance. Emergency power generators that rely on diesel fuel are at constant risk of unexpected failure due to clogged fuel filters when the diesel fuel is allowed to degrade, and contamination occurs. Steps need to be taken to assure a reliable, long-term source of quality diesel fuel for emergency generator systems. The power generator industry standard is to run the backup generator system periodically, maybe once each month, for 30 minutes or until it reaches operating temperature. This is not enough time to allow the diesel fuel to circulate to achieve meaningful filtration. However, the diesel fuel is subjected to injector pump pressure and extreme heat that warms the fuel returning to the storage tank and encourages condensation to form in the tank bottom, providing an attractive environment for microbial contamination to thrive. Fuel filters are changed during regular oil changes, typically twice per year. The amount of run time for the fuel is not enough to allow contaminant build-up on the filter to reveal a diesel fuel contamination problem to the maintenance personnel. Biocide additives are repeatedly added to the same fuel to deal with microbial activity, but this process accelerates fuel deterioration causing solids and debris to settle in the tank. Fuel samples are tested for microbial and fungi activity, but results are negative. Fuel quality, it is mistakenly assumed, is being maintained. As engines are tested, the diesel fuel is continuously re-circulated and exposed to extreme pressure and heat, which results in the accumulation of asphalt Ines, the high carbon content, heavy end fuel molecules. This process leads to the formation of larger and larger clusters and solids, which are very difficult to combust completely. These solids may grow so large that they create larger fuel droplets, too large for efficient combustion.

Why are diesel engines noisy?

The basic engine construction may be the same (although most of the components differ – block, pistons, injectors), but the thermodynamic cycle in which the engine operates is different – the petrol engine operates on the Otto cycle, the diesel engine operates on the Diesel cycle. In a petrol (Otto) engine, the fuel/air mixture is ignited by a spark. A flame front spreads through the cylinder, burning the fuel gradually and slowly compared to a diesel engine, giving a gradual increase in-cylinder pressure. In a diesel engine, fuel is injected into the cylinder; after compression, the air in the cylinder is ignited instantly by heat. This gives a more instant burn, and hence a faster increase in-cylinder pressure. It is this more sudden increase in pressure that causes the characteristic diesel noise.

How do diesel injectors work?

The diesel fuel injection system has undergone many changes over the years. Previously, cars used to have a carburetor installed in them, but such vehicles are no longer on the market. On the other hand, the fuel injection system has been around since the 1950s, and electronic fuel injection (EFI) was installed in European Cars during the 1980s. Almost all fuel injection services, including diesel injection and petrol injection service, will supply fuel injection systems. When people think of the word “diesel,” most people will think of huge trucks releasing many black soot and gases that cause a great deal of harm to the environment. However, most container ships still rely on diesel to travel long distances across the ocean. Diesel is still mainly used in heavy vehicles like trucks.

How does a diesel fuel pump work?

A diesel injection pump uses an injector to spray fuel directly past the glow plug and then flows into the combustion chamber. This technology created here will allow for the complete burning of diesel fuel. It, therefore, makes it more efficient and produces less stinky smoke in the atmosphere.

How does a diesel fuel system work?

The key ingredient to maximizing a diesel engine’s peak performance is increasing diesel being burned. The only way to do this was to modify the injectors and the injection pump on old mechanical injection engines. The new electronic-injection systems have several ways to increase the fuel going into the cylinders. However, ultimately, peak power production still comes down to the injection components’ mechanical limitations that build fuel pressure and inject the diesel into the combustion chambers. The fuel system on most diesel engines is composed of three main parts: the injector, the injection pump, and in some cases, the engine control unit (ECU). In most diesel engines, fuel injectors are mounted in the engine’s cylinder head(s), and the tip or nozzle of the injector sprays directly into the combustion chamber. In many cases, the injector is mounted just like a spark plug in a gas engine. But unlike fuel-injected gas engines that inject fuel at 10-60 psi, diesel fuel-injection systems run in the 10,000-30,000-psi range. The VE pump is a distributor-style, mechanically controlled, axial-piston pump. The engine drives its input shaft, and axial pistons pressurize the fuel. Fuel is fed to the injectors by a port-controlled distributor; this mechanical device controls the timing and quantity of fuel going to each injector.

How does a diesel engine start?

- You turn the key in the ignition.

- A “Start” light goes on.

- Fuel pumps deliver the fuel from the fuel tank to the engine.

- The fuel injection pump pressurizes fuel into a delivery tube.

- The fuel, air, and “fire” meet in the cylinders.

- Combustion spreads from the smaller amount of fuel placed under pressure in the precombustion chamber to the fuel and air in the combustion chamber itself.

How does a diesel generator work?

Diesel generators employ compression ignition for igniting the fuel at high temperatures. The air and fuel are fused at different stages, and the fuel is injected using an injector. It compresses air only at the ratio of 14:1. They can either be two cycles or four cycles.

How does a diesel injection pump work?

An Injection Pump is a device that pumps fuel into the cylinders of a diesel engine. Traditionally, the injection pump is driven indirectly from the crankshaft by gears, chains, or a toothed belt (often the timing belt) that also drives the camshaft. It rotates at half crankshaft speed in a conventional four-stroke engine. Its timing is that the fuel is injected only slightly before the top dead center of that cylinder’s compression stroke. It is also typical for the pump belt on gasoline engines to be driven directly from the camshaft. In some systems, injection pressures can be as high as 200 MPa (30,000 PSI).

When should diesel injectors be replaced?

Diesel injectors fail because of two main reasons. The first has to do with the injector structure’s mechanical soundness, and the second has to do with the quality of the fuel running through the injector. To understand an injector’s workings (and what makes them fail), we contacted Energy Engineering. The company supplied us with many of the images of failed injectors you see here, taken with a microscope, to help you to keep this damage from happening to your diesel.

Why would a diesel engine not start?

Some of the reasons your diesel engine may fail to start include insufficient fuel supply, blocked filters, faulty injectors, and battery failure, among other problems. Your engine could also be experiencing low compression or low fuel pressure. Other issues include having low fuel pressure. You could consult a motor mechanic for more information.

Why would a diesel lose power?

Well, you don’t say what engine you have, but we would suspect that you have a DPF (diesel particulate filter). If so, then it sounds as though it is getting blocked. By driving the car at high revs can sometimes clear the system (like a chimney), but you should carry out a ‘regeneration.’ To do this, you need to run the engine at high revs (between 2000 and 2500) for approx 30 mins.

Which diesel fuel is best?

Most engines are designed to operate on ASTM No. 2-D grade, but some diesel engines in stop-and-go service require No. 1-D diesel fuels for the best results. Check your owner’s manual to determine the right fuel for your vehicle, and be sure to use ULSD in 2007 model vehicles and newer.

Which diesel fuel additive is best?

The diesel engine’s heart is its fuel injection equipment, and the primary enemy of this equipment is low-quality diesel fuel. From our extensive research and testing and our experience in manufacturing diesel fuel injection systems, Stanadyne found that variations in diesel fuel quality worldwide can adversely affect today’s precision fuel injection systems. Low-quality diesel fuel can cause performance issues, premature wear, gumming of components, and plugged filters. To resolve these issues and protect the fuel injection system, Stanadyne developed its line of diesel fuel additives.

Why are diesel injectors so expensive?

The diesel injectors have about 40 moving parts in them that are made to VERY tight tolerances, and there is a lot more that goes into these injectors than any other injector.

Why is diesel green?

All diesel sold in the United States typically has some dye in it. On-road diesel usually has a slight green tint to it. This is a dye added by either the refiner or terminal provider with the fuel. Off-road diesel is dyed red to denote that the fuel is untaxed and used for off-road purposes only.

How do diesel fuel injectors work?

Diesel injectors work by transferring fuel from the supply line to the fuel injector device attached to each cylinder. It is pressurized and then sprayed through a small nozzle into the cylinder’s combustion chamber. Air is sucked in through a valve and mixed with vaporized diesel fuel increasing combustion while the emissions are removed through the exhaust, with any excess fuel returning to the fuel tank.

How does a diesel injection pump work?

The first types of injection pumps were in-line, meaning a pump and plunger unit connected to each engine cylinder. The fuel was inserted into the pump unit, with one end opening to the combustion chamber and the other housing the plunger. The plunger moved back and forth: with the backward stroke, it opened a valve that let the fuel in, and in its forward stroke, it generated a large amount of force that propelled the fuel into the combustion chamber. The chamber’s heated air and pressure instantly ignited the fuel so that no spark plugs were needed. The more modern distributor injection pumps use only one injection pump. Still, it is rotated to meet each combustion chamber as needed and comes with additional valves that control precisely how much fuel is inserted into the pump chamber. By electronically controlling the fuel used with each injection, the maximum amount of fuel can be saved. There are also modern gasoline engines that use the fuel injection system for a similar end. By avoiding the use of spark plugs and controlling fuel use, these engines also work to save energy, this time using less gasoline.

How do diesel generators work?

Diesel generators employ compression ignition for igniting the fuel at high temperatures. The air and fuel are fused at different stages, and the fuel is injected using an injector. It compresses air only at the ratio of 14:1. They can either be two cycles or four cycles.

Why won’t a diesel engine start?

Some of the reasons your diesel engine may fail to start include insufficient fuel supply, blocked filters, faulty injectors, and a flat battery, among other problems. Your engine could also be experiencing low compression or low fuel pressure. Other issues include having low fuel pressure. You could consult a motor mechanic for more information.